In Italy, a country with a long tradition in the craft and industrial sectors, there is a company that has made sustainability its primary mission: TECNOVA, which specializes in the production of complete plastic recycling plants. Founded in Novara, one of the most significant industrial centers in Italy, it has grown over the years to become one of the leading companies in the plastics industry in Italy and worldwide.

TECNOVA is a true example of the importance of adopting sustainable business practices and investing in innovation to address global environmental challenges. Since its foundation, the company, with an in-depth knowledge of post-consumer waste and waste from industrial processing, has focused on studying the specific requirements of plastic regeneration.

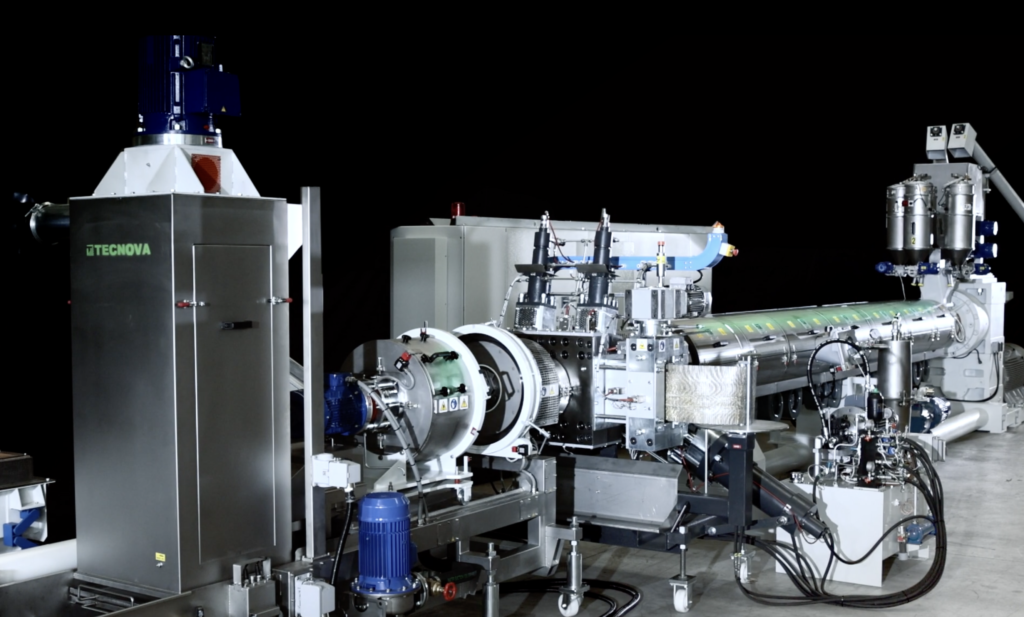

The ability to adapt to the changing market trends has been one of its major strengths. Over the years, it has developed cutting-edge recycling technologies for processing a wide range of plastic polymers, from hard plastics to flexible plastics, from PET to HDPE. Consequently, it has been capable of providing customized solutions to a vast array of sectors, e.g. the automotive, packaging, electronics, and furniture industries.

Sustainability is the company’s primary goal. Thanks to its plants, designed for the processing of medium and large batches, it has made a significant contribution to reducing plastic waste and CO2 emissions compared to producing new plastics. Additionally, the company has initiated a research and development program to continuously improve its process efficiency.

“We have adopted a collaborative approach concerning sustainability – says Marco Massaro, who has recently become sole owner of the company – and established partnerships with companies, institutions, and environmental organizations, such as ARE YOU R, to promote best practices and the development of sustainable solutions for plastic waste management. Over the years, the machines’ quality, reliability, ease of use, and maintenance have enabled us to become a global leader with over 3,000 systems installed worldwide”.

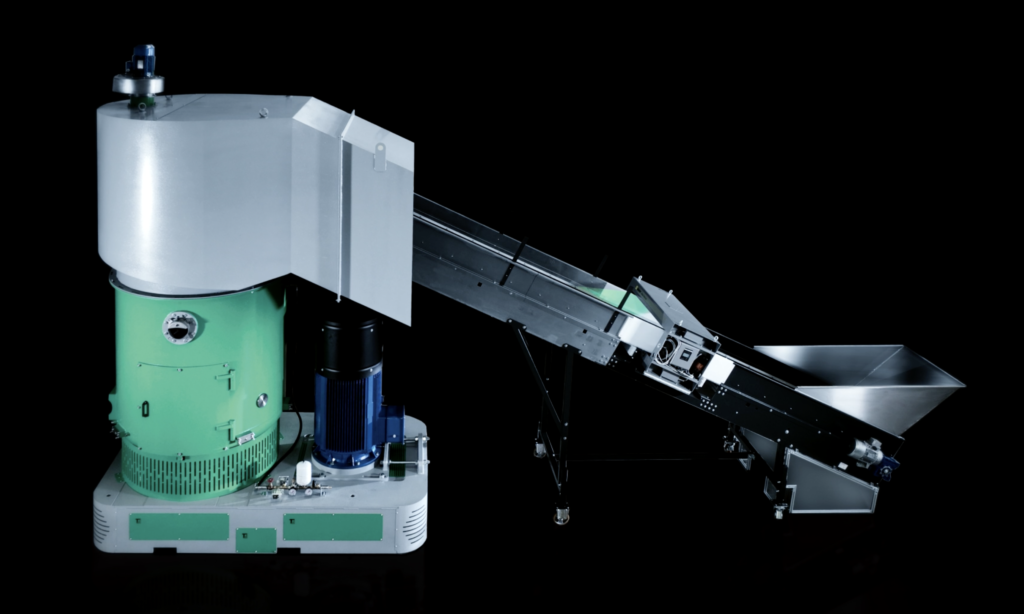

TECNOVA’s true strength lies in its commitment to family values. Recently, the founder Antonio Massaro passed the baton on to his son Marco, which has resulted in new challenges and new opportunities for the company’s future. While the founder benefits from the experience and wisdom acquired over the years, the successor brings freshness and innovative perspectives. A significant example of this is the launch of the LIONTEK densifier, where past and present came together in a strategic project that has already proven successful. First presented to the foreign market during the 2022 edition of the K fair and recently launched in Italy at the PLAST fair in Milan

Liontek adds to the already vast product range designed for the recycling of plastics, including the highly contaminated ones, by TECNOVA, which celebrates its 40th anniversary. Liontek is a closedcircuit densifier studied to process post-consumer, post-industrial, or washing plant plastic material in-line and not in batch. The original project, the drawings of which still circulate in the company, was conceived in 1997 by Antonio Massaro, TECNOVA’s current president, but was initially dropped due to other production priorities. Based on this project, the technical department developed the new plant.

The densifier plays a fundamental role in the processing cycle of plastic waste deriving from both post-consumption and industrial processes. Today, it is increasingly difficult to find material with residual humidity levels lower than 5-10%, perfectly suitable for direct injection into extruders. The function of LIONTEK is essential to reduce the presence of humidity which often compromises the quality of the granule, its processing, and consequently the final output.

It completes the line-up currently available on the market under the TECNOVA brand name and is designed for domestic and foreign customers who already own lines of the same brand, whether new or previously manufactured, but also for those who use other manufacturers’ equipment. LIONTEK can be sold as a stand-alone machine because it is perfectly compatible and can also be combined with third-party systems on the market.

To sum up, the right mix of past and new skills may prove successful for the company, just as maintaining a global vision and an innovative attitude may guarantee its growth and sustainability, as well as for future generations.