We’ve reached the last step of this magical journey to discover plastic recycling!

In the previous articles, we saw how the collection and sorting, cleaning and decontamination, grinding and extrusion of plastic waste work, whereas last time we explained how the material filtration process works.

In this new article, we’ll explain how granulation works, that is another crucial step to turn our waste into useful resources. In this way, the recycling process will be completed.

Granulation is a result of all previous steps of the process.

It’s a key stage, for it enables pellets – which are essential to create new products – to be produced.

What are recycled plastic pellets?

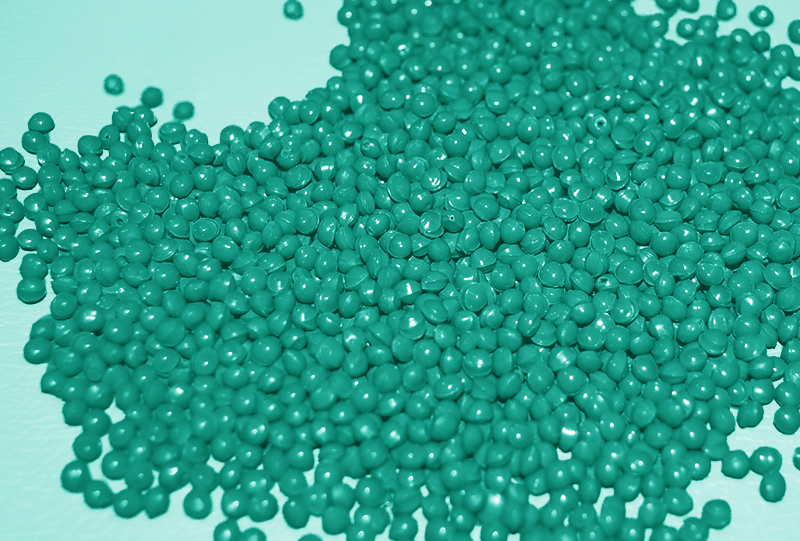

They look like real ‘confetti’ of recycled plastic that take the characteristic shape of granules.

Pellets are used to produce enormous quantities of products from recycled materials according to the specific plastic type – not only durable goods for our everyday life, but also packaging, infrastructure, and construction components.

Want to know more? Read about how much can be made thanks to plastic materials recycling!

How does granulation work?

The granulation process seems to be quite simple but requires certain conditions.

Melted plastic comes out of specific holes, in the form of real ‘spaghetti’, which are subsequently cut with appropriate knifes. That way, depending on the diameter of the holes and the rotational speed of the blades, it’s possible to obtain pellets with variable diameter and length, also according to the different needs of the finished product that must be obtained.

Here are some practical examples of recycled plastic pellets! These tiny, colourful pieces result from the commitment of every consumer who disposes waste properly. Thanks to recycling, what we dispose today can be turned into a new, useful product. All of us can be part of this ‘magic’ – contributing to preserving our environment.

Now we just have to create new ready-to-use recycled plastic products!

Thank you for being with us!